Adiabatic cutting presses

Adiabatic cutting is the transposition of the cutting of long products to flat products. The adiabatic impact received by the cutting punches generates a shearing band that propagates through the thickness of the sheet and according to the contour of the punch. The part is cut precisely from the sheet even before the punch passes through the whole thickness.

From the standpoint of quality of parts, the adiabatic cutting performed by ADIAPRESS ® offers the following advantages:

The adiabatic cutting tools have a special design that takes the speeds achieved into account, but operate according to the progressive tool principle. The strip layouts are advantageous compared to conventional cutting and fine cutting because the low deformation of the material allows the pieces to be brought very close together. This reduces the cutting pitch and the width of the strips, which saves significant quantities of material.

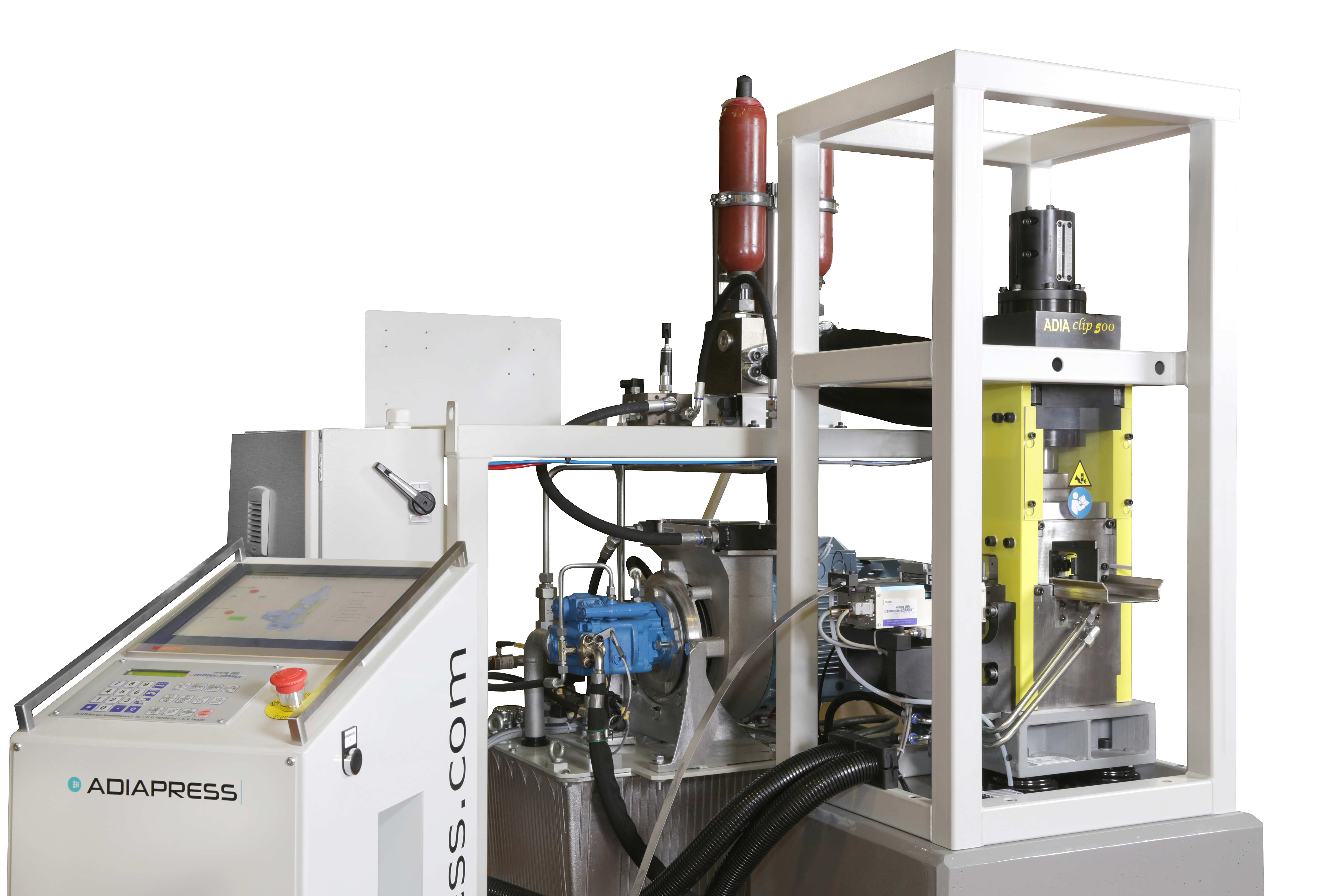

ADIAPRESS ® designs and develops adiabatic cutting presses that are independent or integrates them with commercially-available peripherals used to work from sheet metal reels (dispensers, straighteners, feed systems). In all cases, the lines have a high productivity level thanks to the frequency and the SMED tool-changing logic.

The cutting presses are usable for:

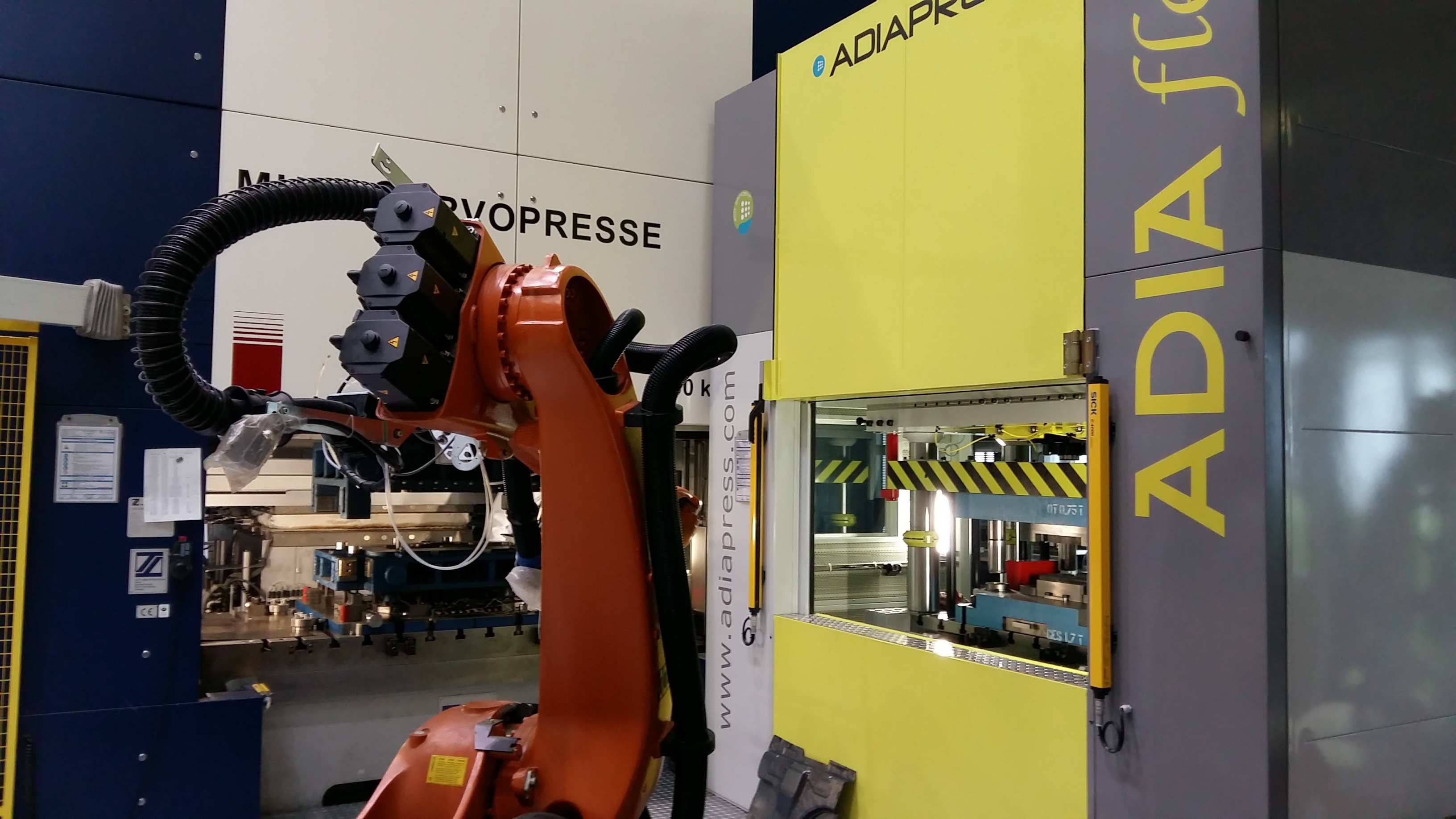

In addition to cutting presses with spools, the ADIAflex range is designed for the repeat cutting of large parts (bodywork components) previously stamped or hardened in a press. ADIAflex has several mobile striking heads, to operate in the right location. Its robotic loading and unloading system gives it great overall flexibility.